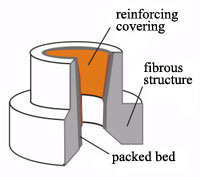

Fibrous Refractories was the first company of its kind in Russia to start producing shell-type riser sleeves, both of a gas-pressure type with exothermal substances heating and a heat-insulating, adiabatic type, on a large-lot basis in 2008. Our products can be delivered with breaker cores to aid the process of riser removal or without them.

When in use, the riser sleeves produced by our company are highly technologically sound and will achieve the following results:

- Up to a 25-percent increase in cast yield when it comes to large-mould casting;

- Up to a 40-percent reduction in the amount of metal consumption in the process of casting;

- Decrease in machining allowances intended for the post-casting mechanical treatment of crop parts from15-20 to 4-5 mm;

- Reduction in expenditure for metal-working tools in the process of post-casting treatment;

- No necessity in the use of fire-cutting for riser removal;

- Optional accommodation of riser over any surface without any harm to the casting configuration;

- Development in the quality of the casting process in terms of reducing the effects related to shrinkage (shells, friability, cracks) and unsolicited extraneous inclusions (gas and non-metal inclusions)

- Serial production of riser sleeves in accordance with a specific client`s needs (the shape and size of the covering, geometrical parameters of breaker cores so as to enhance the process of riser removal, heat-retaining capability, an exothermal-reaction unit, a controlled time of the delay in combustion initiation)

The exothermal mixtures we use have the following characteristics:

- Low combustion temperature;

- Stable process of burning at a controlled speed;

- The use of exothermal mixtures results in up to a twofold delay in solidification;

- Good thermal-insulation characteristics of the mixtures once the exothermal process is finished;

- Absence of the chemical interaction between the mixtures and the metal in the riser;

- Low smoke and fume;

- absence of the pyroelectric effect;

- High endurance throughout all the stages of the process;

- Absence of mechanical metal penetration;

- High gas permeability.

|

|

|

|

|

|